![]()

Adaptors & Backshell Assemblies - Definitions & Technical Overview

DEFINITIONS and KEY TYPES

For high performance sealing and strain relief, offering the perfect solution for harsh environment wiring applications. Rayfast offers a variety of adapters for applications in many industries, including aerospace, marine and mass transit.

These adapters are:

• Available in many configurations to match applications.

• Easy to install.

• Ideal for high-reliability applications.

• Kitted for customer convenience.

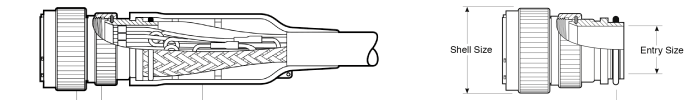

In this section we present an outline of Solid and Spin Coupling adaptors to more specialist Spin-Lock, Shielded and Tinel-Lock adapters, plus accessories. The Tinel-Lock adapter utilises the unique Tinel ring to terminate the overall shield to the adapter. The Tinel

ring is a low-profile, high strength, shape-memory alloy shield-termination device available in many sizes

to accommodate various entry sizes and shield configurations.

Download the PDF for Definitions and Key Types

SELECTING MATERIAL & FINISH

To ensure optimum compatibility, select the adaptor material and finish to match those of the connector. Additional materials and finishes are also available on request. Further information is available in the PDF below.

Download the PDF for Selecting Material and Finish

DETERMINE THE ENTRY SIZE

Once you have the wire bundle size, you can use the chart below to select the entry size. This chart shows the

minimum entry size for cables from 3mm to 38mm in diameter. In other words, the white spaces on the chart

represent all of the cable outside diameters each entry size will fit. Following these steps:

1. Find the cable diameter on the chart

2. Note the lowest entry size that will fit the cable diameter

If the adaptor is shielded or has a Tinel-Lock® ring, there are additional considerations, which are noted in the PDF below.

Download the PDF for Determine the Entry Size

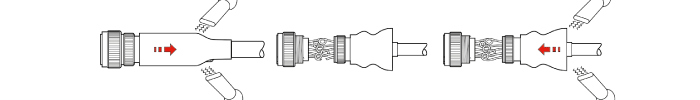

ROLL-BACK REPAIR FOR ADAPTORS

More than 85% of cable repairs are made within 75mm of the connector, usually as a result of a broken pin or wire. By reheating the

heat-shrinkable moulded part and unscrewing the adaptor coupling nut, the moulded part can be “rolled back”, providing access to the rear of the connector. This technique is applicable to spin-coupling, shielded and Tinel-Lock® (TXR) adaptors (providing there are wire

loops, then the broken pin or wire can be repaired using this technique). A code of practice is available on request.

Download the PDF for Roll-Back Repair

For further information please see either the PDF links above, or for additional assistance please contact us:

USA Sales: Phone us on +1 (317) 244 6643 or email us at usasales@rayfast.com

UK/Europe Sales: Phone us on +44(0) 1793 439144 or email us at uksales@rayfast.com

Authorised Distributor for TE Connectivity

Raychem Wire, Harness, Protection & Identification Products

Terms & Conditions | GDPR | Privacy Policy | Trademarks & Disclaimer | Sitemap | Download Adobe